- F

- L

- E

- X

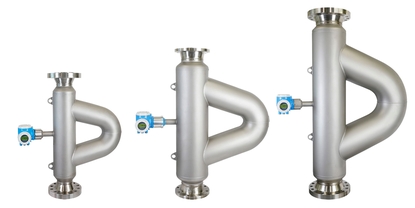

Proline Promass Q 500 with different remote transmitters

- F

- L

- E

- X

Proline Promass Q 500

- F

- L

- E

- X

The German Innovation Award recognizes industry-wide products that set themselves apart from currently-available solutions through their added value.

Proline Promass Q 500 with different remote transmitters

Specs at a glance

-

Max. measurement error

Mass flow (liquid): ±0.10 % (standard), 0.05 % (option)

Volume flow (liquid): ±0.10 %

Mass flow (gas): ±0.25 %

Density (liquid): +/-0.2 kg/m³ (standard), +/-0.1 kg/m³ (option) -

Measuring range

0 to 2 400 000 kg/h (0 to 88183 lb/min)

-

Medium temperature range

Standard: –50 to +205°C (–58 to +401 °F)

Option: –196 to +150 °C (–321 to +302 °F) -

Max. process pressure

PN 100, Class 600, 63K

-

Wetted materials

Measuring tube: 1.4404 (316/316L); stainless steel for cryogenic applications

Connection: 1.4404 (316/316L)

Field of application

Promass Q 500 provides the highest measurement accuracy for mass flow, volume flow and density. Being the preferred choice for custody transfer applications, it has also been optimized for liquid applications where entrained gas is known to be present. With its innovative remote transmitter Promass Q 500 maximizes installation flexibility and operational safety in demanding environments. Heartbeat Technology enables safe processes.

Measuring principle operates independently of physical fluid properties such as viscosity or density

Highest measurement performance for custody transfer, density and under tough process conditions.

Device properties

Mass / volume flow: measurement error ±0.05 % (PremiumCal)

Density: measurement error ±0.1 kg/m³ (optional)

High turndown due to low pressure loss/zero point

Compact dual-compartment housing with up to 3 I/Os

Backlit display with touch control and WLAN access

Remote display available

Benefits

Secured measuring quality – unmatched accuracy of mass flow, volume flow and density

Optimized performance for liquids with entrained gas – MFT (Multi-Frequency Technology)

Fewer process measuring points – multivariable measurement (flow, density, temperature)

Space-saving installation – no in-/outlet run needs

Full access to process and diagnostic information – numerous, freely combinable I/Os and Ethernet

Reduced complexity and variety – freely configurable I/O functionality

Integrated verification – Heartbeat Technology

Videos

-

Grisard Bitumen relies on Promass Q with 4-tube technology

-

Promass Q with 4-tube technology – The new standard in the oil and gas industry

-

Proline Promass Q optimizes measurement in receiving of raw milk with unwanted entrained air at the dairy Meierei Barmstedt

-

Ensure consistency, taste and texture in your products with the exceptionally accurate and continuous overrun measurement of Proline Promass Q

-

Measure the sugar concentration in your beverages in real time thanks to inline density measurement with Proline Promass Q

-

Proline Promass Q - The flow specialist for the exact measurement of liquids with entrained gas

Xpert selection

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

Could also interest you

-

Measuring principle

Coriolis

-

Product headline

Innovative specialist for challenging applications, as remote version with up to 4 I/Os.

Secured measuring quality – unmatched accuracy of mass flow, volume flow and density.

Highest measurement performance for custody transfer, density and under tough process conditions. -

Sensor features

Optimized performance for liquids with entrained gas – MFT (Multi-Frequency Technology). Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in-/outlet run needs.

Mass flow: measurement error ±0.05 % (PremiumCal). Density: measurement error ±0.2 kg/m³. High turndown due to low pressure loss/zero point. -

Transmitter features

Full access to process and diagnostic information – numerous, freely combinable I/Os and fieldbuses. Reduced complexity and variety – freely configurable I/O functionality. Integrated verification – Heartbeat Technology.

Remote version with up to 4 I/Os. Backlit display with touch control and WLAN access. Standard cable between sensor and transmitter. -

Nominal diameter range

DN 25 to 250(1 to 10")

-

Wetted materials

Measuring tube: 1.4404 (316/316L); stainless steel for cryogenic applications

Connection: 1.4404 (316/316L) -

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density, concentration

-

Max. measurement error

Mass flow (liquid): ±0.10 % (standard), 0.05 % (option)

Volume flow (liquid): ±0.10 %

Mass flow (gas): ±0.25 %

Density (liquid): +/-0.2 kg/m³ (standard), +/-0.1 kg/m³ (option) -

Measuring range

0 to 2 400 000 kg/h (0 to 88183 lb/min)

-

Max. process pressure

PN 100, Class 600, 63K

-

Medium temperature range

Standard: –50 to +205°C (–58 to +401 °F)

Option: –196 to +150 °C (–321 to +302 °F) -

Ambient temperature range

Standard: - 4 to +60 °C (–4 to +140 °F)

Option:–60 to +60 °C (–76 to +140 °F) -

Sensor housing material

1.4404 (316L), highest corrosion resistance

Sensor connection housing (standard): AlSi10Mg, coated

Sensor connection housing (option): 1.4301 (304); 1.4404 (316L); 1.4409 (CF3M) similar to 316L -

Transmitter housing material

AlSi10Mg, coated; 1.4409 (CF3M) similar to 316L; Polycarbonat

-

Degree of protection

Sensor remote version (standard): IP66/67, type 4X enclosure

Sensor remote version (option): IP69. Transmitter remote version: IP66/67, Type 4X enclosure -

Display/Operation

4-line backlit display with touch control (operation from outside)

Configuration via local display and operating tools possible -

Outputs

4 outputs:

4-20 mA HART (active/passive)

4-20 mA WirelessHART

4-20 mA (active/passive)

Pulse/frequency/switch output (active/passive)

Double pulse output (active/passive)

Relay output -

Inputs

Status input

4-20 mA input -

Digital communication

HART, PROFIBUS DP, PROFIBUS PA, FOUNDATION Fieldbus, Modbus RS485, PROFINET, PROFINET over Ethernet-APL, Ethernet/IP, OPC-UA

-

Power supply

DC 24 V

AC 100 to 230 V

AC 100 to 230 V / DC 24 V (non-hazardous area) -

Hazardous area approvals

ATEX, IECEx, cCSAus, NEPSI, INMETRO, EAC, KC

-

Product safety

CE, C-tick, EAC marking

-

Functional safety

Functional safety according to IEC 61508, applicable in safety-relevant applications in accordance with IEC 61511

-

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025)

Heartbeat Technology complies with the requirements for measurement traceability according to ISO 9001:2015 – Section 7.1.5.2 a (TÜV SÜD attestation)

MI-005 Liquids other than water (Hydrocarbons, Liquified gases, Cryogenic liquids)

OIML R117 (Liquids other than water, Liquified gases, Cryogenic liquids)

NTEP (Liquids other than water, Cryogenic liquids)

MC (Liquids other than water, Cryogenic liquids) -

Marine approvals and certificates

LR approval, DNV approval, ABS approval, BV approval, CCS approval

-

Pressure approvals and certificates

PED, CRN, AD 2000

-

Material certificates

3.1 material

NACE MR0175/MR0103, PMI; welding test acc. to EN ISO, ASME, NORSOK -

Hygienic approvals and certificates

3-A, EHEDG, cGMP

-

Measuring principle

Coriolis

-

Product headline

Innovative specialist for challenging applications, as remote version with up to 4 I/Os.

Secured measuring quality – unmatched accuracy of mass flow, volume flow and density.

Highest measurement performance for custody transfer, density and under tough process conditions. -

Sensor features

Optimized performance for liquids with entrained gas – MFT (Multi-Frequency Technology). Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in-/outlet run needs.

Mass flow: measurement error ±0.05 % (PremiumCal). Density: measurement error ±0.2 kg/m³. High turndown due to low pressure loss/zero point. -

Transmitter features

Full access to process and diagnostic information – numerous, freely combinable I/Os and fieldbuses. Reduced complexity and variety – freely configurable I/O functionality. Integrated verification – Heartbeat Technology.

Remote version with up to 4 I/Os. Backlit display with touch control and WLAN access. Standard cable between sensor and transmitter. -

Nominal diameter range

DN 25 to 250(1 to 10")

-

Wetted materials

Measuring tube: 1.4404 (316/316L); stainless steel for cryogenic applications

Connection: 1.4404 (316/316L) -

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density, concentration

-

Max. measurement error

Mass flow (liquid): ±0.10 % (standard), 0.05 % (option)

Volume flow (liquid): ±0.10 %

Mass flow (gas): ±0.25 %

Density (liquid): +/-0.2 kg/m³ (standard), +/-0.1 kg/m³ (option) -

Measuring range

0 to 2 400 000 kg/h (0 to 88183 lb/min)

-

Max. process pressure

PN 100, Class 600, 63K

-

Medium temperature range

Standard: –50 to +205°C (–58 to +401 °F)

Option: –196 to +150 °C (–321 to +302 °F) -

Ambient temperature range

Standard: - 40 to +60 °C (–40 to +140 °F)

Option:–60 to +60 °C (–76 to +140 °F) -

Sensor housing material

1.4404 (316L), highest corrosion resistance

Sensor connection housing (standard): AlSi10Mg, coated

Sensor connection housing (option): 1.4301 (304); 1.4404 (316L); 1.4409 (CF3M) similar to 316L -

Transmitter housing material

AlSi10Mg, coated; 1.4409 (CF3M) similar to 316L; Polycarbonat

-

Degree of protection

IP66/67, type 4X enclosure. Transmitter remote version: IP66/67, Type 4X enclosure

-

Display/Operation

4-line backlit display with touch control (operation from outside)

Configuration via local display and operating tools possible -

Outputs

4 outputs:

4-20 mA HART (active/passive)

4-20 mA WirelessHART

4-20 mA (active/passive)

Pulse/frequency/switch output (active/passive)

Double pulse output (active/passive)

Relay output -

Inputs

Status input

4-20 mA input -

Digital communication

HART, PROFIBUS DP, PROFIBUS PA, FOUNDATION Fieldbus, Modbus RS485, PROFINET, PROFINET over Ethernet-APL, Ethernet/IP, OPC-UA

-

Power supply

DC 24 V

AC 100 to 230 V

AC 100 to 230 V / DC 24 V (non-hazardous area) -

Hazardous area approvals

ATEX, IECEx, cCSAus, NEPSI, INMETRO, EAC, KC

-

Product safety

CE, C-tick, EAC marking

-

Functional safety

Functional safety according to IEC 61508, applicable in safety-relevant applications in accordance with IEC 61511

-

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025)

Heartbeat Technology complies with the requirements for measurement traceability according to ISO 9001:2015 – Section 7.1.5.2 a (TÜV SÜD attestation)

MI-005 Liquids other than water (Hydrocarbons, Liquified gases, Cryogenic liquids)

OIML R117 (Liquids other than water, Liquified gases, Cryogenic liquids)

NTEP (Liquids other than water, Cryogenic liquids) -

Marine approvals and certificates

LR approval, DNV approval, ABS approval, BV approval, CCS approval

-

Pressure approvals and certificates

PED, CRN, AD 2000

-

Material certificates

3.1 material

NACE MR0175/MR0103, PMI; welding test acc. to EN ISO, ASME, NORSOK -

Hygienic approvals and certificates

3-A, EHEDG, cGMP

-

Measuring principle

Coriolis

-

Product headline

Innovative specialist for challenging applications, as remote version with up to 4 I/Os.

Secured measuring quality – unmatched accuracy of mass flow, volume flow and density.

Highest measurement performance for custody transfer, density and under tough process conditions. -

Sensor features

Optimized performance for liquids with entrained gas – MFT (Multi-Frequency Technology). Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in-/outlet run needs.

Mass flow: measurement error ±0.05 % (PremiumCal). Density: measurement error ±0.2 kg/m³. High turndown due to low pressure loss/zero point. -

Transmitter features

Full access to process and diagnostic information – numerous, freely combinable I/Os and fieldbuses. Reduced complexity and variety – freely configurable I/O functionality. Integrated verification – Heartbeat Technology.

Remote version with up to 4 I/Os. Backlit display with touch control and WLAN access. Standard cable between sensor and transmitter. -

Marine approvals and certificates

LR approval, DNV approval, ABS approval, BV approval

-

Measuring principle

Coriolis

-

Product Headline

Innovative specialist for challenging applications, as remote version with up to 4 I/Os.

Secured measuring quality – unmatched accuracy of mass flow, volume flow and density.

Highest measurement performance for custody transfer, density and under tough process conditions. -

Sensor features

Optimized performance for liquids with entrained gas – MFT (Multi-Frequency Technology). Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in-/outlet run needs.

Mass flow: measurement error ±0.05 % (PremiumCal). Density: measurement error ±0.2 kg/m³. High turndown due to low pressure loss/zero point. -

Transmitter features

Full access to process and diagnostic information – numerous, freely combinable I/Os and fieldbuses. Reduced complexity and variety – freely configurable I/O functionality. Integrated verification – Heartbeat Technology.

Remote version with up to 4 I/Os. Backlit display with touch control and WLAN access. Standard cable between sensor and transmitter. -

Nominal diameter range

DN 25 to 250(1 to 10")

-

Wetted materials

Measuring tube: 1.4404 (316/316L); stainless steel for cryogenic applications

Connection: 1.4404 (316/316L) -

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density, concentration

-

Max. measurement error

Mass flow (liquid): ±0.10 % (standard), 0.05 % (option)

Volume flow (liquid): ±0.10 %

Mass flow (gas): ±0.25 %

Density (liquid): +/-0.2 kg/m³ (standard), +/-0.1 kg/m³ (option) -

Measuring range

0 to 2 400 000 kg/h (0 to 88183 lb/min)

-

Max. process pressure

PN 100, Class 600, 63K

-

Medium temperature range

Standard: –50 to +205°C (–58 to +401 °F)

Option: –196 to +150 °C (–321 to +302 °F) -

Ambient temperature range

Standard: - 40 to +60 °C (–40 to +140 °F)

Option:–50 to +60 °C (–58 to +140 °F) -

Sensor housing material

1.4404 (316L), highest corrosion resistance

Sensor connection housing (standard): AlSi10Mg, coated

Sensor connection housing (option): 1.4301 (304); 1.4404 (316L); 1.4409 (CF3M) similar to 316L -

Transmitter housing material

AlSi10Mg, coated; 1.4409 (CF3M) similar to 316L; Polycarbonat

-

Degree of protection

Sensor remote version (standard): IP66/67, type 4X enclosure

Sensor remote version (option): IP69. Transmitter remote version: IP66/67, Type 4X enclosure -

Display/Operation

4-line backlit display with touch control (operation from outside)

Configuration via local display and operating tools possible -

Outputs

4 outputs:

4-20 mA HART (active/passive)

4-20 mA WirelessHART

4-20 mA (active/passive)

Pulse/frequency/switch output (active/passive)

Double pulse output (active/passive)

Relay output -

Inputs

Status input

4-20 mA input -

Digital communication

HART, PROFIBUS DP, PROFIBUS PA, FOUNDATION Fieldbus, Modbus RS485, PROFINET, PROFINET over Ethernet-APL, Ethernet/IP, OPC-UA

-

Power supply

DC 24 V

AC 100 to 230 V

AC 100 to 230 V / DC 24 V (non-hazardous area) -

Hazardous area approvals

ATEX, IECEx, cCSAus, NEPSI, INMETRO, EAC, KC

-

Other approvals and certificates

CE, C-tick, EAC marking

Functional safety according to IEC 61508, applicable in safety-relevant applications in accordance with IEC 61511

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025)

Heartbeat Technology complies with the requirements for measurement traceability according to ISO 9001:2015 – Section 7.1.5.2 a (TÜV SÜD attestation)

MI-005 Liquids other than water (Hydrocarbons, Liquified gases, Cryogenic liquids)

OIML R117 (Liquids other than water, Liquified gases, Cryogenic liquids)

NTEP (Liquids other than water, Cryogenic liquids)

MC (Liquids other than water, Cryogenic liquids)

LR approval, DNV approval, ABS approval, BV approval

PED, CRN, AD 2000

3.1 material

NACE MR0175/MR0103, PMI; welding test acc. to EN ISO, ASME, NORSOK

3-A, EHEDG, cGMP

-

Measuring principle

Coriolis

-

Product headline

Innovative specialist for challenging applications, as remote version with up to 4 I/Os.

Secured measuring quality – unmatched accuracy of mass flow, volume flow and density.

Highest measurement performance for custody transfer, density and under tough process conditions. -

Sensor features

Optimized performance for liquids with entrained gas – MFT (Multi-Frequency Technology). Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in-/outlet run needs.

Mass flow: measurement error ±0.05 % (PremiumCal). Density: measurement error ±0.2 kg/m³. High turndown due to low pressure loss/zero point. -

Transmitter features

Full access to process and diagnostic information – numerous, freely combinable I/Os and fieldbuses. Reduced complexity and variety – freely configurable I/O functionality. Integrated verification – Heartbeat Technology.

Remote version with up to 4 I/Os. Backlit display with touch control and WLAN access. Standard cable between sensor and transmitter. -

Nominal diameter range

DN 25 to 250(1 to 10")

-

Wetted materials

Measuring tube: 1.4404 (316/316L); stainless steel for cryogenic applications

Connection: 1.4404 (316/316L) -

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density, concentration

-

Max. measurement error

Mass flow (liquid): ±0.10 % (standard), 0.05 % (option)

Volume flow (liquid): ±0.10 %

Mass flow (gas): ±0.25 %

Density (liquid): +/-0.2 kg/m³ (standard), +/-0.1 kg/m³ (option) -

Measuring range

0 to 2 400 000 kg/h (0 to 88183 lb/min)

-

Max. process pressure

PN 100, Class 600, 63K

-

Medium temperature range

Standard: –50 to +205°C (–58 to +401 °F)

Option: –196 to +150 °C (–321 to +302 °F) -

Ambient temperature range

Standard: - 4 to +60 °C (–4 to +140 °F)

Option:–60 to +60 °C (–76 to +140 °F) -

Sensor housing material

1.4404 (316L), highest corrosion resistance

Sensor connection housing (standard): AlSi10Mg, coated

Sensor connection housing (option): 1.4301 (304); 1.4404 (316L); 1.4409 (CF3M) similar to 316L -

Transmitter housing material

AlSi10Mg, coated; 1.4409 (CF3M) similar to 316L; Polycarbonat

-

Degree of protection

IP66/67, type 4X enclosure. Transmitter remote version: IP66/67, Type 4X enclosure

-

Display/Operation

4-line backlit display with touch control (operation from outside)

Configuration via local display and operating tools possible -

Outputs

4 outputs:

4-20 mA HART (active/passive)

4-20 mA WirelessHART

4-20 mA (active/passive)

Pulse/frequency/switch output (active/passive)

Double pulse output (active/passive)

Relay output -

Inputs

Status input

4-20 mA input -

Digital communication

HART, PROFIBUS DP, PROFIBUS PA, FOUNDATION Fieldbus, Modbus RS485, PROFINET, PROFINET over Ethernet-APL, Ethernet/IP, OPC-UA

-

Power supply

DC 24 V

AC 100 to 230 V

AC 100 to 230 V / DC 24 V (non-hazardous area) -

Hazardous area approvals

ATEX, IECEx, cCSAus, NEPSI, INMETRO, EAC, KC

-

Product safety

CE, C-tick, EAC marking

-

Functional safety

Functional safety according to IEC 61508, applicable in safety-relevant applications in accordance with IEC 61511

-

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025)

Heartbeat Technology complies with the requirements for measurement traceability according to ISO 9001:2015 – Section 7.1.5.2 a (TÜV SÜD attestation)

MI-005 Liquids other than water (Hydrocarbons, Liquified gases, Cryogenic liquids)

OIML R117 (Liquids other than water, Liquified gases, Cryogenic liquids)

NTEP (Liquids other than water, Cryogenic liquids) -

Marine approvals and certificates

LR approval, DNV approval, ABS approval, BV approval, CCS approval

-

Pressure approvals and certificates

PED, CRN, AD 2000

-

Material certificates

3.1 material

NACE MR0175/MR0103, PMI; welding test acc. to EN ISO, ASME, NORSOK -

Hygienic approvals and certificates

3-A, EHEDG, cGMP

-

-

Technical Information (TI)

TI Proline Promass Q 500

English version - 11/2024

New version available in English

Coriolis flowmeter

EN 01/11/202401/08/202201/01/202116/09/201915/07/2019Language:

English

Version:

01/11/2024

File size:

11.4 MB

File name:

TI01287DEN_1024-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass Q 500

English version - 11/2024

New version available in English

Coriolis flowmeter HART

EN 01/11/202401/08/202201/01/202101/09/201902/10/2017Language:

English

Version:

01/11/2024

File size:

9.7 MB

File name:

BA01534DEN_0724-00.pdf

-

-

-

Technical Information (TI)

TI Proline Promass Q 500

-

Technical Information (TI)

English version - 11/2024New version available in EnglishCoriolis flowmeter

EN 01/11/202401/08/202201/01/202116/09/201915/07/2019Language:

English

Version:

01/11/2024

File size:

11.4 MB

File name:

TI01287DEN_1024-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass Q 500

-

Operating Instruction (BA)

English version - 11/2024New version available in EnglishCoriolis flowmeter

PROFIBUS DPEN 01/11/202401/01/202101/06/2018Language:

English

Version:

01/11/2024

File size:

8.4 MB

File name:

BA01878DEN_0324-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass Q 500

-

Operating Instruction (BA)

English version - 11/2024New version available in EnglishCoriolis flowmeter

PROFIBUS PAEN 01/11/202401/01/202101/11/201801/11/2016Language:

English

Version:

01/11/2024

File size:

8.7 MB

File name:

BA01556DEN_0524-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass Q 500

-

Operating Instruction (BA)

English version - 11/2024New version available in EnglishCoriolis flowmeter

FOUNDATION FieldbusEN 01/11/202401/01/202101/11/2016Language:

English

Version:

01/11/2024

File size:

8.5 MB

File name:

BA01567DEN_0324-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass Q 500

-

Operating Instruction (BA)

English version - 11/2024New version available in EnglishCoriolis flowmeter

PROFINETEN 01/11/202401/01/202116/09/201915/07/201902/10/2017Language:

English

Version:

01/11/2024

File size:

11.5 MB

File name:

BA01766DEN_0524-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass Q 500

-

Operating Instruction (BA)

English version - 11/2024New version available in EnglishCoriolis flowmeter

PROFINET over Ethernet-APLEN 01/11/202408/01/2024Language:

English

Version:

01/11/2024

File size:

9.5 MB

File name:

BA02129DEN_0224-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass Q 500

-

Operating Instruction (BA)

English version - 11/2024New version available in EnglishCoriolis flowmeter

HARTEN 01/11/202401/08/202201/01/202101/09/201902/10/2017Language:

English

Version:

01/11/2024

File size:

9.7 MB

File name:

BA01534DEN_0724-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass Q 500

-

Operating Instruction (BA)

English version - 11/2024New version available in EnglishCoriolis flowmeter

EtherNet/IPEN 01/11/202401/01/202102/10/2017Language:

English

Version:

01/11/2024

File size:

10 MB

File name:

BA01755DEN_0324-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass Q 500

-

Operating Instruction (BA)

English version - 11/2024New version available in EnglishCoriolis flowmeter

Modbus RS485EN 01/11/202401/08/202201/01/202101/09/201901/12/2018Language:

English

Version:

01/11/2024

File size:

9.1 MB

File name:

BA01545DEN_0824-00.pdf

-

-

-

Device Parameter (GP)

GP Proline Promass 500

-

Device Parameter (GP)

English version - 05/2024New version available in EnglishCoriolis flowmeter

PROFINET over Ethernet-APLEN 17/05/202408/01/2024Language:

English

Version:

17/05/2024

File size:

3.3 MB

File name:

GP01173DEN_0224-00.pdf

-

Choose from our suggested options

-

-- selected coding-- selected label99.999,00<%label%>

-

Looking for more options? Please use the individual configurator to continue

-

-- selected coding-- selected label99.999,00<%feature%>

-

<%label%>99.999,00

-

Looking for more options? Please use the individual configurator to continue

-

Process Connection

-

<%label%>99.999,00

-

<%label%>99.999,00

-

-

<%feature%><%coding%><%label%>

- CAD drawings CAD drawings

- CAD drawings

-

Prices per piece

-

<%range%><%price%>

-

- Optional add-ons

Individual configuration

Often bought together

Accessories

Related products

We value your privacy

We use cookies to enhance your browsing experience, collect statistics to optimize site functionality, and deliver tailored advertisements or content.

By selecting "Accept all", you consent to our use of cookies.

For further details please review our cookie policy .