Process safety in chemical industry operations is vital, particularly when working with materials that are hazardous to people, the environment, and infrastructure. Maintaining safety compliance whilst ensuring consistency of output, high productivity, and cost effectiveness, is the primary challenge facing today’s chemical manufacturer.

Key facts

234 mil.

tons of ammonia

is the forecasted global demand for ammonia by 2021 according to the Fertilizer Outlook summary report of the Annual International Fertilizer Association (IFA) Conference 2017.

Improve the safety of your chemical processes

Click through these process maps and learn how we handle your critical parameters.

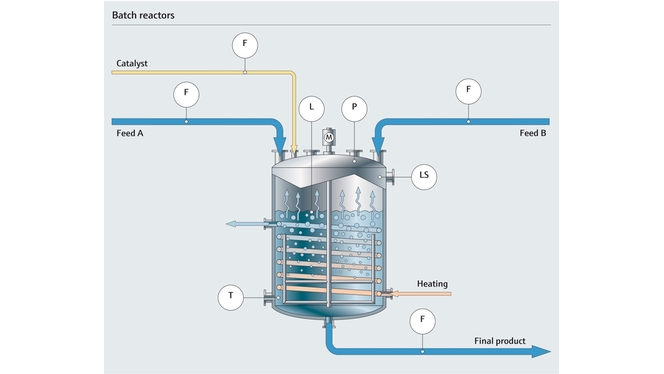

Safer flow measurement in the batch reactor with intrinsically safe real two-wire device.

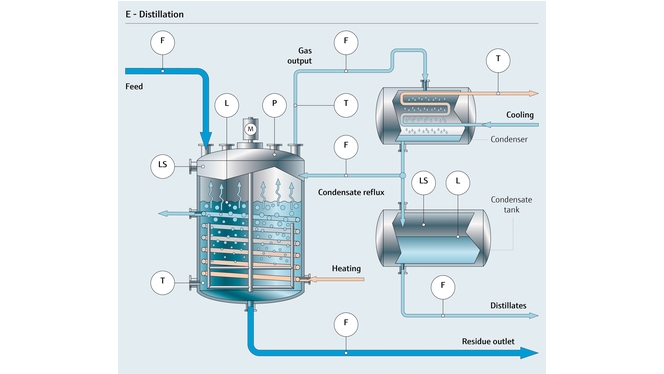

Transparent metering in your distillation process to receive reliable data of e.g. level detection of ammonia.

Cover multiple measuring points with only one temperature assembly using our MultiSens Flex TMS01 & TMS02 (approved by pressure regulations such as PED, ASME VIII).

Safer flow measurement in the batch reactor with intrinsically safe real two-wire device.

Transparent metering in your distillation process to receive reliable data of e.g. level detection of ammonia.

Cover multiple measuring points with only one temperature assembly using our MultiSens Flex TMS01 & TMS02 (approved by pressure regulations such as PED, ASME VIII).

Accurate measurement for product batch purity

Consistent product quality and purity requires reliable, transparent and accurate metering of critical process parameters, as does ensuring a safe and efficient production process.

Our expertise in the field

Endress+Hauser equips your batch reactor with real two-wire devices for

Ammonia level detection in the separator

Evaporation of liquid chemicals such as ammonia or alcohols from water creates risks when heating the vessel. Maintaining the appropriate levels is critical, and yet controlling these levels requires highly sophisticated and accurate instrumentation and techniques.

Our expertise in the field

The innovative Endress+Hauser

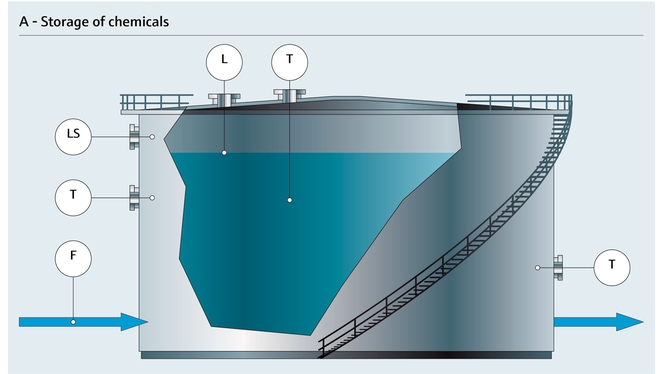

Ammonia temperature detection in the storage tank

Ammonia is a toxic gas when kept at room temperature, explaining why it is best to store it in its liquid state at -33 °C (-27.4 F). Measuring the temperature of both the fluid and the tank walls is essential for the avoidance of hotspots, however as accessing the filled tank is unfeasible, highly robust and accurate sensor technologies are required.

Our expertise in the field

Combining Endress+Hauser

Benefits

A safe chemical process and environment is of the utmost importance in our society. That’s why chemical plant operators carry a special responsibility with regards to safety of their process and for the environment. To fulfill this responsibility they need a trustful partner. We support chemical plant operators as well as engineers and managers by answering any questions about how our instruments and solutions can heighten the safety of their processes and increase efficiency.

Key facts

up to 40%

downtime reduced using HistoROM data management concept for fast and easy commissioning, maintenance and diagnostics.

Key facts

50%

of your time saved thanks to easy proof test concept according to SIL/WHG.

Key facts

up to 30%

is the amount of measuring points which are covered with only one temperature assembly using our MultiSens Flex TMS01 & TMS02, available according to international pressure regulations (e.g. PED, ASME VIII).

How we can help

Fully compliant to current safety standards, the Endress+Hauser portfolio of safety measurement technologies spans the critical parameters of complex chemical processes such as extraction, reaction, separation, and filtration, to ensure maximal process control with sustained plant availability and safety.

- Broadest safety measurement portfolio developed according to safety by design and fulfilling hazardous area standards: e.g. ATEX, FM, TIIS

- Smart sensors with functional safety according to IEC61508, up to SIL 3 for documented proof testing procedures

- Worldwide support network of safety expertise

- Safety and standards (e.g. ATEX. SIL, WHG) seminars and training for plant personnel