Facing volatile commodity prices on the one side and complex customer demands on the other, the need for optimized processes within the cement industry has never been higher. Think for example of the energy costs in the clinker manufacturing process, which can represent up to 75% of the variable costs. But to efficiently lower your expenses without compromising the quality of your products, accurate process data derived from reliable instruments is key.

Key facts

65-75 %

energy cost

of the overall costs are not uncommon within cement manufacturing. But there are ways to optimize the process.

Raw meal and clinker silo monitoring

In order to keep production going it is necessary to continuously monitor stock levels in the raw meal and clinker silos. As storage vessels come in many shapes and sizes, level monitoring can be a challenge.

Our expertise in the field

Endress+Hauser offers many different level monitoring technologies and solutions, designed for challenging environments like dust and abrasion.

- Our

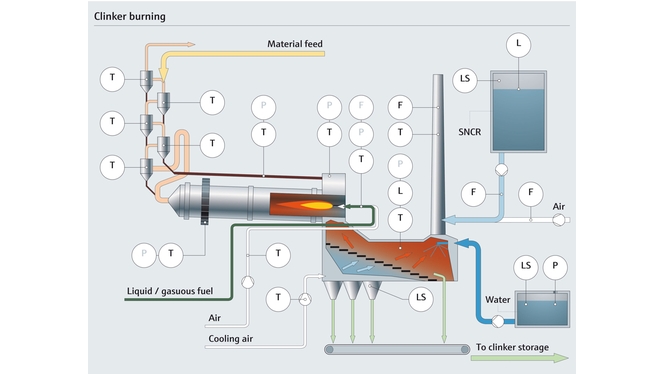

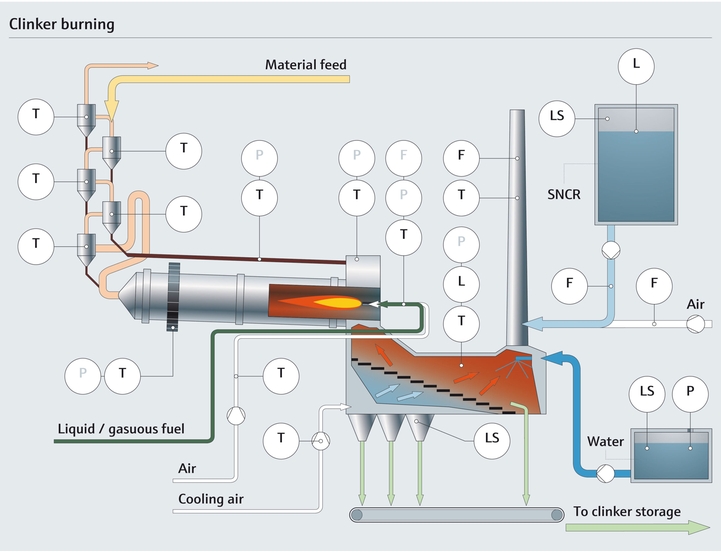

Kiln burner control and fuel oil dosing

Pyroprocessing is generally regarded as the heart of cement production. It is the stage in which most of the operating costs of cement manufacturing appear, and is also therefore the area where most of the opportunities for process improvement exist.

Our expertise in the field

The main parameter for these processes is naturally temperature. By monitoring it, you can ensure a consistent product quality and optimize fuel consumption.

- For temperature measurement in the upper cyclones of the preheater, use a

Clinker cooler monitoring

The clinker cooler is one of the most critical applications in cement production as the rate of cooling can be critical to the clinker quality and overall performance of cement.:

Our expertise in the field

Thanks to our comprehensive portfolio we can offer a whole clinker cooler monitoring package all from one source. This includes:

- Differential pressure sensors for metering and monitoring cooling air consumption

- Flow meters for air cooling and

Cyclone preheater instrumentation

Cyclone preheaters need to be monitored to control the blending of the the raw meal and to prevent blockages which could result in costly down-time.

Our expertise in the field

Apart from temperature as a base parameter for overall efficiency , measuring pressure and actual build-up can help detecting blockages.

- Latest in high-tech, abrasion-proof alloy

Benefits

E+H industry consultants have together with our customers achieved remarkable results and improved plant optimization whilst maintaining high levels of operational safety in many industry sectors like precious metals, cement and steel production. Apart from our technical expertise and the industry optimized product portfolio the basis for such success is our business creed. We believe in building long-lasting relations with customers and not just short term profits.

Key facts

145,000+

smart level sensors in cement silos worldwide

Key facts

60+

years of experience in measurement instrumentation

Key facts

10 million

devices installed worldwide

How we can help

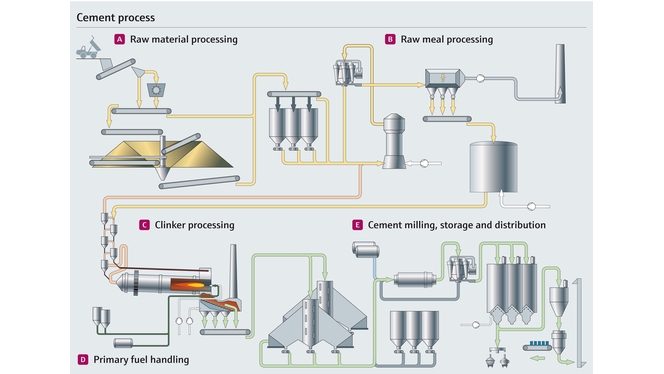

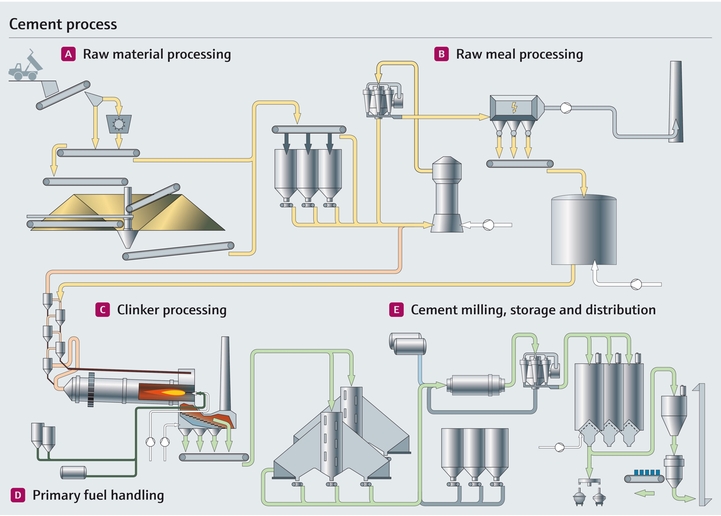

Whether you are managing a project, automating a fuel handling system, selecting instruments for your clinker process or packaging a NOx gas cleaning solution for your environmental compliance program, our experienced process automation consultants can handle all measurement and control requirements of fully-integrated cement plants:

- Raw meal and clinker silo monitoring

- Kiln burner control and fuel oil dosing package

- Clinker cooler monitoring

- Cyclone preheater instrumentation

- Storage and dosing of additives