Continuous Brix measurement of soft drinks

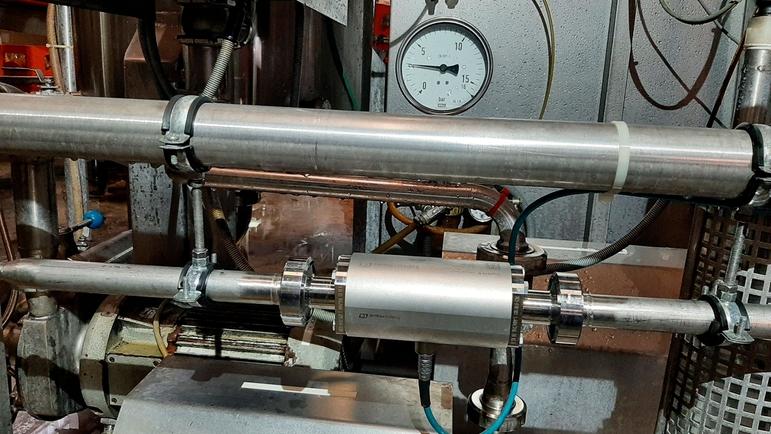

Teqwave H replaces manual refractometer measurement at Kreuzberg Quelle

Kreuzberg Quelle wanted to automate the monitoring of the sugar/invert sugar content in the soft drink filling process and was looking for an inline measuring device. Endress+Hauser offers the ideal solution with the concentration meter Teqwave H. Its state-of-the-art calculation methods enable compensation for cross-influences on a product-specific basis. This enables determining the sugar content of a wide variety of non-alcoholic beverages very accurately in the process.

The results

-

Continuous measurement of the sugar concentration in soft drinks without time-consuming manual sample measurement

-

Increased measuring accuracy thanks to product-specific recipes that allow compensation for cross-influences

-

Simplified documentation by calling up internally stored measured data

-

Enhanced flexibility by reading out measured values and adjusting the recipes thanks to the digital communication protocol (Modbus TCP)

-

Robust hygienic design and very simple in-line cleaning of the sensor

The challenge

Kreuzberg Quelle had previously used a handheld refractometer to monitor the Brix content during the filling process to ensure consistent quality of their soft drinks. Measuring samples of each batch manually was time-consuming and fluctuations were discovered late in the process. Therefore, they were looking for a concentration meter that monitors the Brix content continuously and eliminates the effect of cross-influences. They also wanted to monitor the measured values from various places.

Our solution

The concentration meter Teqwave H continuously measures the sugar content in various soft drinks in real time. With configurable product-specific recipes the customer can compensate for existing cross-influences (acid, CO2) and thus boost the measuring accuracy. Measured values can be read out anytime and anywhere thanks to digital communication. Deviation from set point as well as large fluctuations in the measured values can be identified quickly and product quality is ensured.

Device used

Teqwave H with “Softdrink” concentration app for measuring the sugar concentration and creating product-specific recipes for soft drinks with different acid and CO2 content

Teqwave Viewer operating software for reading out stored data

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |