When first installed, mechanical meters work fine. But better measurement alternatives will ensure maximum process safety and performance, and prevent your precious time and energy being spent on instrument maintenance. Why compromise your processes, or risk an expensive shutdown because of aging technology that has reached its limits? It’s time to replace mechanical meters and other outdated measurement technologies with instrumentation that reliably performs under all process conditions.

Key facts

4,100

USD/ hour

is the price for stopping the process completely, assuming a liquid flow velocity of 2.0 m/s, a standard DN 50/ line, a flow rate around 15,000l/ hour, with a value of 0.30 USD/ l.

Click through to see how you can improve process performance

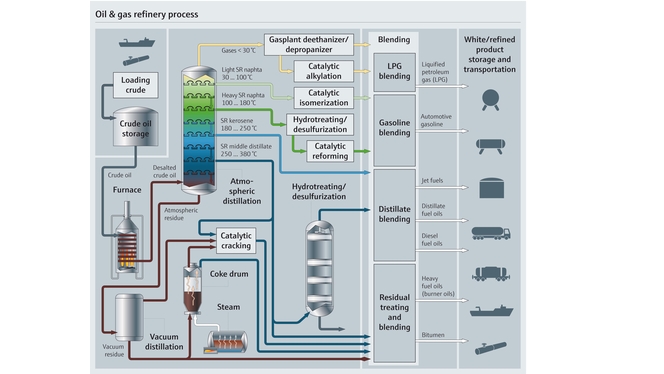

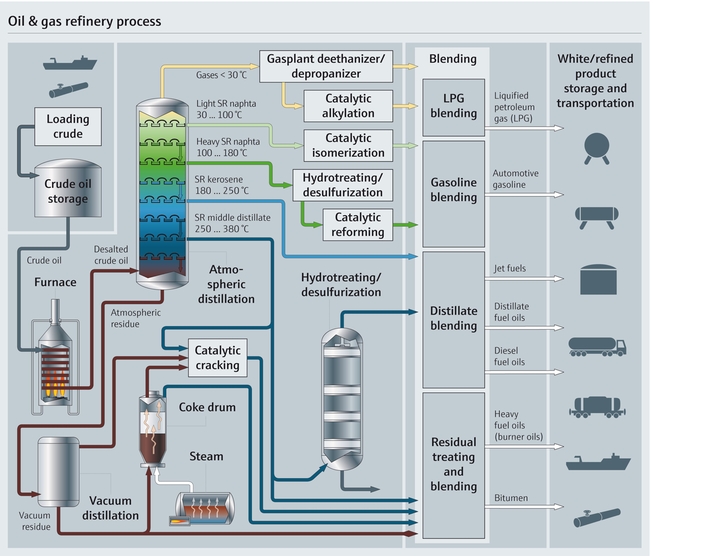

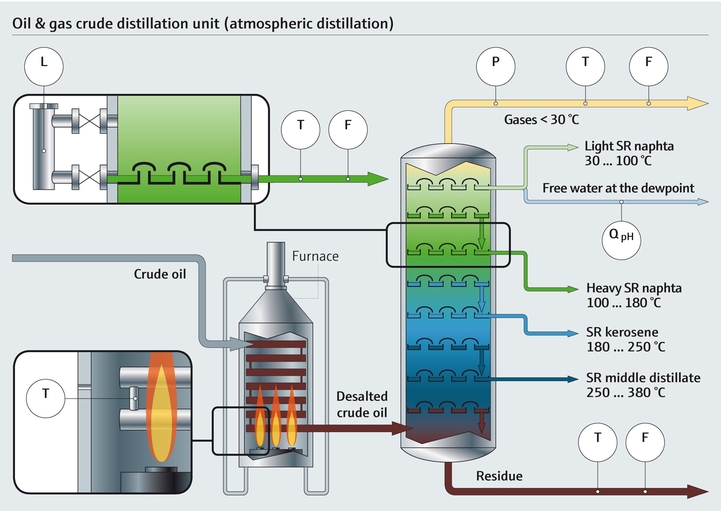

The refining process

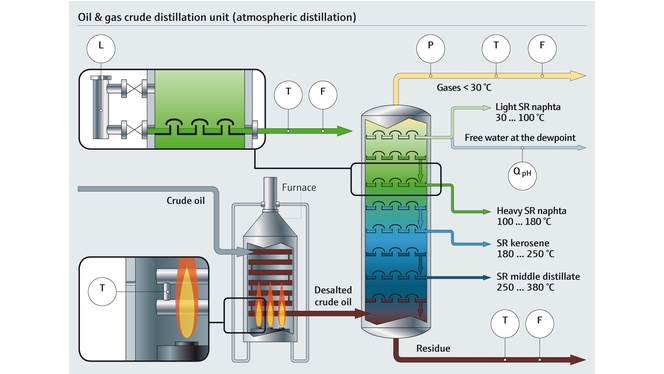

The distillation column

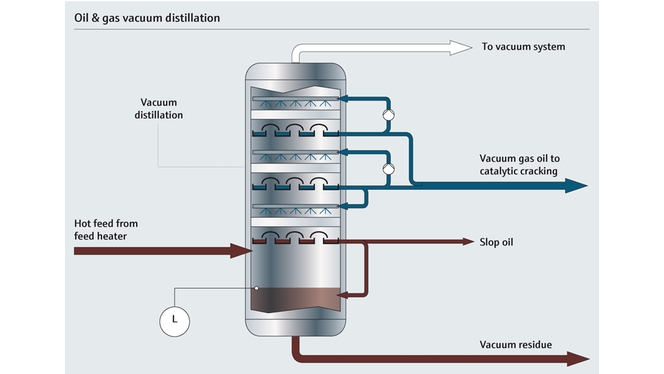

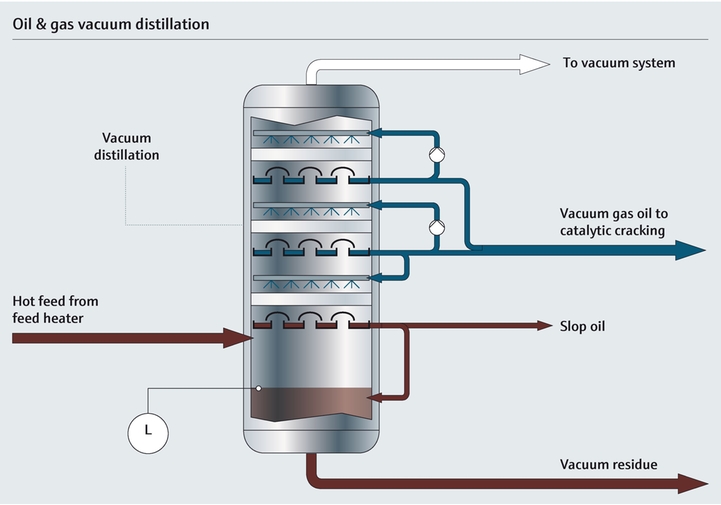

The vacuum distillation column

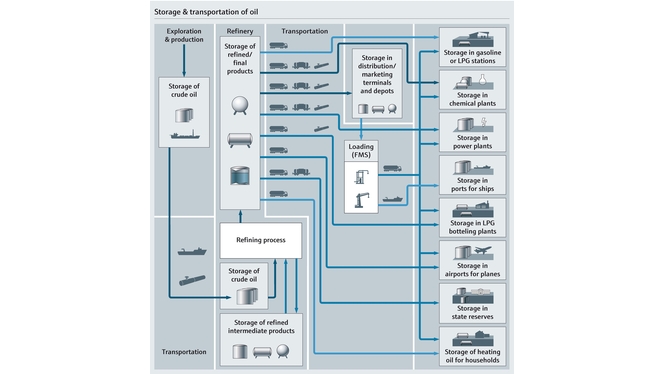

Storage and transportation

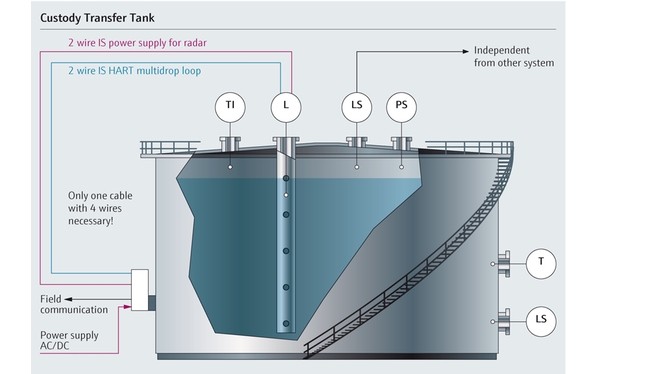

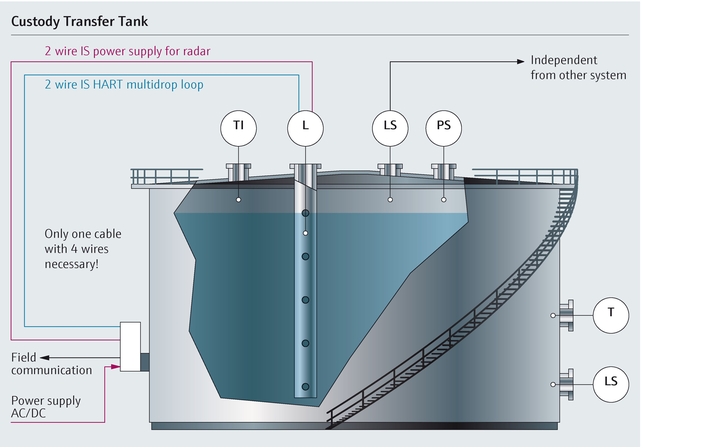

Static custody transfer tank

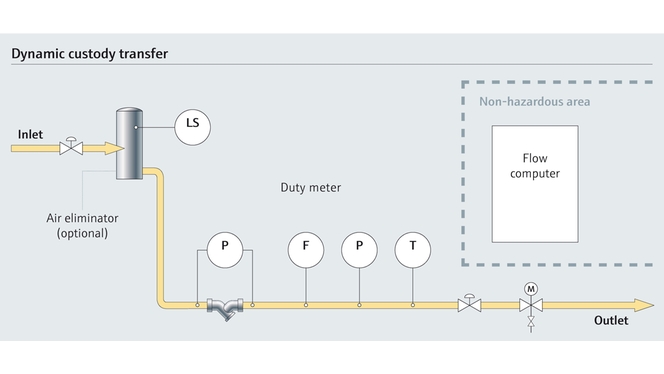

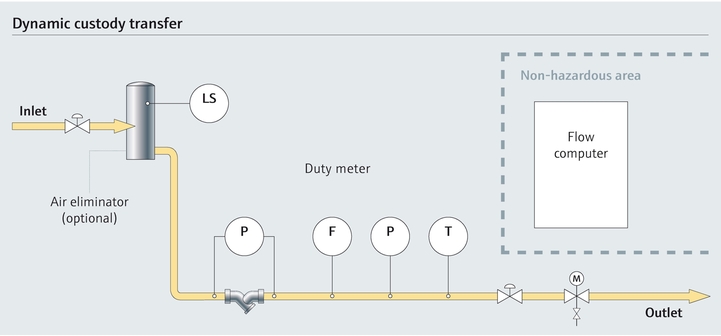

Dynamic custody transfer

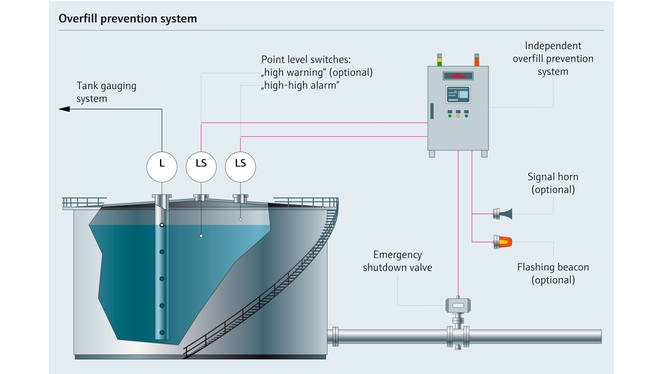

Safely monitor your tank and prevent hazardous overflow with an intelligent system that is able to operate by itself.

Reliable, efficient well fluid separation

Floats and displacers are still widely used for interface and overall level measurements. But they need a lot of maintenance to ensure accuracy, along with continuous adjustments for varying crude oil densities. This can result in high maintenance efforts in remote crude oil gathering units.

Our expertise in the field

With modern accurate guided wave radar or radiometric measuring technologies, you reduce maintenance and assure crude oil quality, ready to dispatch to the refinery.

Chemical injection skids: protection and performance

Chemical injections into process lines and fluids are daily business in oilfield services and in the production & processing of oil and gas. Each chemical injection skid has its own critical measuring tasks.

Our expertise in the field

Endress+Hauser offers a full range of measurement instrumentation that performs under harsh conditions, together with skid design services to protect your people and infrastructure, improve productivity, reduce costs, and avoid downtime.

- Reduce chemical consumption and improve control with Coriolis flowmeters: Two-wire technology saves weight and space, sensor is resistant to internal clogging thanks to self-draining measuring tube

- Prevent over or under pressurization to ensure effective injection with accurate with quick-response pressure measurement

- Rely on guided radar level measurement with multiecho tracking and Heartbeat technology

Distillation column and vacuum distillation

Maximizing the feed rate of the crude distillation column while ensuring the mixture of crude types meets environmental specifications is a must. Modernizing your level measurement technologies can avoid costly shutdowns. In vacuum distillation, varying ambient temperatures jeopardizes the reliability of traditional differential pressure (dp) measurement using capillaries. In addition, mechanical and thermal impacts can destroy the capillaries every few months.

Our expertise in the field

Guided wave radar (Levelflex) level measurement in the distillation column is the reliable alternative to displacers (compliant with API2350 – functional safety) as it is not affected by density and temperature changes.

- Avoid faulty measurement and vacuum distillation downtime with a reliable, accurate, and responsive electronic dp system

- Minimize process risks

Precise density measurement under real-world conditions

Accurate density measurement is essential for volumetric custody transfer applications and meter proving. Density is also a key indicator of process fluid quality. Legacy liquid density transducers drift over time, requiring regular recalibration, and are sensitive to changing process conditions and fluid properties like viscosity.

Our expertise in the field

Eliminate these disadvantages with a modern densitometer that guarantees unequaled density measurement under fluctuating, real-world conditions.

- Achieve greater precision under real process conditions with the Promass Q Coriolis flowmeter

- Highest measurement accuracy for mass flow, density and temperature, with real-time compensation for fluctuating process conditions

- Assured product quality with Heartbeat technology

- Save time – no maintenance or calibration effort needed

Storage tanks

Floats are very often used in level applications because of their costs. Nevertheless, their reliability is affected by density variations, and they are prone to build-up over time which causes inaccurate or no (jamming/ blocking) measurement. This leads to high maintenance costs due to needed regular cleaning and dismantling, and proof testing is therefore time consuming and made difficult.

Our expertise in the field

Replacing your floats with vibronic limit switches can lead to gain in availability and safety.

- Spend less time in maintenance, checking and cleaning

- Benefit from self-monitoring devices with SIL3 capabilities (compliance with API 2350)

- Proof testing intervals up to 12 years

Fuel transfer

Existing flow meter technologies such as positive displacement (PD), turbine, variable area (VA or Rotameter) and differential pressure (DP) - once the best-fit or only solution for some applications - are no longer the only choice.

Our expertise in the field

Today, modern flow technologies such as vortex, ultrasonic and Coriolis are much more reliable alternatives, especially when a plant's process needs improvement. Endress+Hauser offers a wide range of different devices.

- Intrinsically safe

- Cost savings in respect of cabling work

- Superior performance and less maintenance

- Direct mass flow measurement

Benefits

At Endress+Hauser, we are driven by a spirit of innovation always with your benefits in mind. We make sure to provide you with the best solutions while ensuring process safety. Our experienced team of engineers help design and select the right meters for your critical measuring points. We believe in sustainable relationships and are here for the long haul.

Key facts

287

patent applications filed in 2018

Key facts

50%

total cost of ownership savings offered by electronic dP

Key facts

>30 million

field instruments installed worldwide

Our offering

Our commitment to you is to support, service, and optimize your processes, wherever you are located around the globe. We bring our industry expertise, process knowledge, a uniform approach with clear procedures, and best alternative technologies to support your shift from aging mechanical meters and other outdated instrumentation. In short, we help you ensure that critical measuring tasks are entrusted to modern, accurate, and reliable technologies to safeguard your process performance.

- Compliance with safety API 2350 recommendations

- Reduced engineering and commissioning time

- Greater process availability & reliability, and reduced maintenance costs

- Increased output and better product quality; lowest total cost of ownership

- Integrated diagnostics, verification and monitoring; safe processes ensured by Heartbeat technology. Proof testing intervals up to 12 years