Specs at a glance

-

Max. measurement error

Mass flow (liquid): ±0.1 %

Volume flow (liquid): ±0.1 %

Mass flow (gas): ±0.5 %

Density (liquid): ±0.0005 g/cm³ -

Measuring range

0 to 180 000 kg/h (0 to 6600 lb/min)

-

Medium temperature range

–50 to +150 °C (–58 to +302 °F)

-

Max. process pressure

PN 100, Class 600, 63K

-

Wetted materials

Measuring tube: Titanium grade 9

Connection: Titanium grade 2

Field of application

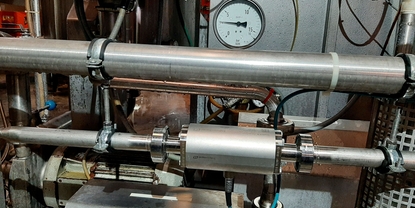

The straight single-tube design of the Promass I 100, provides the regular Coriolis flowmeter outputs of mass flow, density and temperature, additionally it provides in-line viscosity measurement as an optional output.

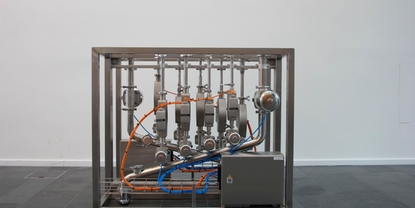

Combined with the smallest transmitter housing available today it delivers full performance on the smallest footprint. Promass I 100 will be the preferred choice for system integrators, skid builders and equipment manufacturers.

Measuring principle operates independently of physical fluid properties such as viscosity or density

Measuring liquids and gases in applications requiring low pressure loss and gentle fluid treatment.

Device properties

Straight, easy cleanable single-tube system

TMB® technology

Measuring tube made of Titanium

Robust, ultra-compact transmitter housing

High ingress protection: IP69K

Local display available

Benefits

Energy-saving – full bore design enables minimal pressure loss

Fewer process measuring points – multivariable measurement (flow, density, temperature)

Space-saving installation – no in/outlet run needs

Space-saving transmitter – full functionality on smallest footprint

Time-saving local operation without additional software and hardware – integrated web server

Integrated verification – Heartbeat Technology

Videos

Xpert selection

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

Predecessor

-

-

Operating Instruction (BA)

BA Proline Promass I 100

English version - 11/2024

Coriolis flowmeter PROFINET

EN 01/11/202401/01/202101/12/2015Language:

English

Version:

01/11/2024

File size:

4.1 MB

File name:

BA01429DEN_0324-00.pdf

-

-

-

Technical Information (TI)

TI Proline Promass I 100

English version - 11/2024

Coriolis flowmeter

EN 01/11/202401/01/202101/12/201510/06/201419/09/2013Language:

English

Version:

01/11/2024

File size:

6 MB

File name:

TI01035DEN_0724-00.pdf

-

-

-

Technical Information (TI)

TI Proline Promass I 100

Coriolis flowmeter

EN 01/11/202401/01/202101/12/201510/06/201419/09/2013Language:

English

Version:

01/11/2024

File size:

6 MB

File name:

TI01035DEN_0724-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass I 100

Coriolis flowmeter

Modbus RS485EN 01/11/202401/01/202101/04/201301/06/2012Language:

English

Version:

01/11/2024

File size:

3.5 MB

File name:

BA01058DEN_0424-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass I 100

Coriolis flowmeter

PROFINETEN 01/11/202401/01/202101/12/2015Language:

English

Version:

01/11/2024

File size:

4.1 MB

File name:

BA01429DEN_0324-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass I 100

Coriolis flowmeter

EtherNet/IPEN 01/11/202401/01/202131/12/201401/04/201301/06/2012Language:

English

Version:

01/11/2024

File size:

3.9 MB

File name:

BA01066DEN_0524-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass I 100

Coriolis flowmeter

PROFIBUS DPEN 01/11/202401/01/202131/12/201419/09/2013Language:

English

Version:

01/11/2024

File size:

4 MB

File name:

BA01251DEN_0424-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Promass I 100

Coriolis flowmeter

HARTEN 01/11/202401/01/202110/06/201401/04/2013Language:

English

Version:

01/11/2024

File size:

4.8 MB

File name:

BA01190DEN_0424-00.pdf

-

-

-

Device Parameter (GP)

Proline Promass 100 HART Description of Device Parameters

Coriolis flowmeter

EN 01/10/201701/12/2015Language:

English

Version:

01/10/2017

File size:

1.9 MB

File name:

GP01033DEN_0217.pdf

-

-

-

Device Parameter (GP)

Proline Promass 100 PROFIBUS DP Description of Device Parameters

Coriolis flowmeter

EN 01/10/201701/12/2015Language:

English

Version:

01/10/2017

File size:

1.7 MB

File name:

GP01034DEN_0217.pdf

-

-

-

Device Parameter (GP)

Proline Promass 100 Modbus RS485 Description of Device Parameters

Coriolis flowmeter

EN 01/10/201723/12/2015Language:

English

Version:

01/10/2017

File size:

1 MB

File name:

GP01035DEN_0217.pdf

-

-

-

Device Parameter (GP)

Proline Promass 100 PROFINET Description of Device Parameters

Coriolis flowmeter

EN 01/10/201701/12/2015Language:

English

Version:

01/10/2017

File size:

1.4 MB

File name:

GP01037DEN_0217.pdf

-

-

-

Device Parameter (GP)

Proline Promass 100 EtherNet/IP Description of Device Parameters

Coriolis flowmeter

EN 01/10/201723/12/2015Language:

English

Version:

01/10/2017

File size:

1.5 MB

File name:

GP01036DEN_0217.pdf

-

-

-

Short Instruction (KA)

Proline 100 Modbus RS485 Brief Operating Instructions

Transmitter with

Coriolis sensorEN 01/10/2017Language:

English

Version:

01/10/2017

File size:

2.4 MB

File name:

KA01335DEN_0117.pdf

-

-

-

Short Instruction (KA)

Proline Promass Brief Operating Instructions

Proline Promass

Part 1 of 2

Coriolis sensorEN 01/04/201701/08/201601/12/2015Language:

English

Version:

01/04/2017

File size:

833.3 KB

File name:

KA01212DEN_0317.pdf

-

-

-

Short Instruction (KA)

Proline Promass I 100 Brief Operating Instructions

Coriolis flowmeter

EN 14/09/201531/12/201410/06/201419/09/201301/04/2013Language:

English

Version:

14/09/2015

File size:

2.5 MB

File name:

KA01117DEN_0615.pdf

-

-

-

Short Instruction (KA)

KA Proline 100 PROFINET

Transmitter with

Coriolis sensorEN 20/12/202401/10/2017Language:

English

Version:

20/12/2024

File size:

1.7 MB

File name:

KA01336DEN_0224-00.pdf

-

-

-

Short Instruction (KA)

KA Proline 100 PROFINET

Part 2 of 2

TransmitterEN 20/12/202401/12/2015Language:

English

Version:

20/12/2024

File size:

1.4 MB

File name:

KA01215DEN_0224-00.pdf

-

-

-

Short Instruction (KA)

Proline 100 PROFIBUS DP Brief Operating Instructions

Transmitter with

Coriolis sensorEN 01/10/2017Language:

English

Version:

01/10/2017

File size:

2.4 MB

File name:

KA01333DEN_0117.pdf

-

-

-

Short Instruction (KA)

Flowmeter Proline Promass I

Coriolis sensor

EN 01/08/202201/02/2017Language:

English

Version:

01/08/2022

File size:

773.9 KB

File name:

KA01284DEN_0222-00.pdf

-

-

-

Short Instruction (KA)

KA Proline 100 EtherNet/IP

Transmitter with

Coriolis sensorEN 20/12/202401/10/2017Language:

English

Version:

20/12/2024

File size:

2.1 MB

File name:

KA01332DEN_0224-00.pdf

-

-

-

Short Instruction (KA)

KA Proline 100 HART

Transmitter with

Coriolis sensorEN 20/12/202401/10/2017Language:

English

Version:

20/12/2024

File size:

2.5 MB

File name:

KA01334DEN_0224-00.pdf

-