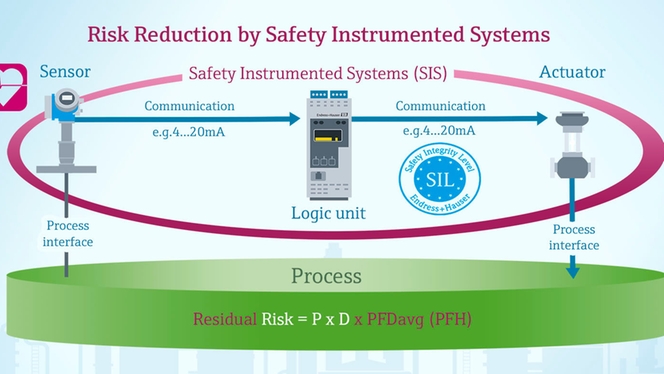

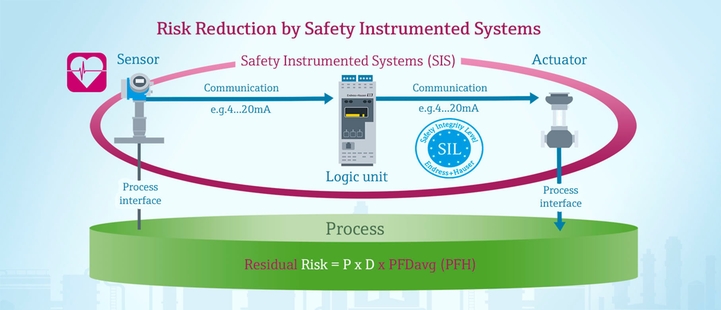

Proof testing Safety Instrumented Systems (SIS) has become a key challenge for the worldwide chemical industry. Such systems are increasingly commonplace for compliance or performance purposes and require regular testing to ensure alignment to standards and processes. Faced with tough competition and reduced margins, the problem for plant operators becomes how to optimize testing methods to ensure costly downtime is minimized, and to do so with the benefit of full, in-depth diagnostic coverage.

Key facts

15%

of measurement technology used in the chemical industry is process control safety equipment

Increase plant safety and availability with minimal effort

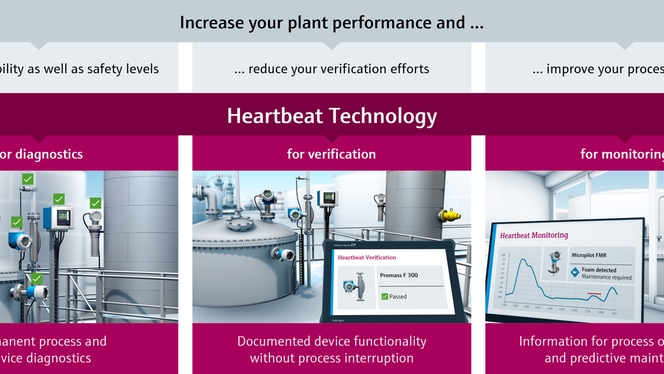

Process and device diagnostics

Undetected instrument failures can increase the probability of an outage in a Safety Instrumented System. Reliable and accurate sensor diagnostics are required to ensure safety and avoid downtime.

Our expertise in the field

Endress+Hauser Heartbeat self-diagnostic sensor technology facilitates timely and accurate diagnosis of instrument faults. Our smart instruments carry out more than 80 internal diagnostic measures in the background, including in-depth diagnostic coverage of up to 98%. Results can be conveniently monitored via our Netilion Health app, which provides transparent and standardized diagnostic messages for simplified intervention.

- Ensure safe processes with minimal process interruption

- Drive cost-effective maintenance through smart data and diagnostics

- Enable targeted, timely and cost-effective maintenance interventions

Documented verification

Verification of instruments is a critical activity for ensuring that the installed base is running correctly, however it must be conducted with minimal interruption to processes.

Our expertise in the field

Endress+Hauser Heartbeat Technology enables instrument verification to be triggered at any time. The automatically generated verification protocol provides precise results, and the evidence required by safety regulations. We also offer a wizard-guided procedure for SIL proof tests, guiding you step by step through the test.

- Extract documented and unambiguous verification results

- Reduce verification effort during planned shutdown periods

- Gain flexibility in SIS proof test planning

Smart monitoring

Regular proof testing is required to ensure ongoing process safety however it decreases system availability.

Our expertise in the field

Powered by Heartbeat Technology, Endress+Hauser instrumentation provides detailed instrument and process data enabling the detection of trends, and by extension predictive maintenance interventions. Our clients can optimize their interventions and extend proof test intervals without compromising safety.

- Implement predictive maintenance based on real-time data

- Optimize processes and maintenance to increase efficiency and safety

- Extend proof test interval for increased system availability

Outsourced SIL proof testing

Chemical industry regulations stipulate regular and documented proof testing of Safety Instrumented Systems, placing an increased burden on plant operations, not only in terms of downtime and process interruption, but on plant personnel availability, certification and training needs.

Our expertise in the field

Our SIL proof testing service enables you to outsource this vital task, from onsite inspection, through proof testing to documentation. Our certified functional safety experts can perform the full range of tests from simple loop tests to customized tests in complex applications.

- Improve plant safety with risk and fault identification

- Reduce unplanned downtime with preventative checks

- Ensure compliance with safety standards and regulations

Benefits

As a chemical plant operator, you carry a special responsibility with regards to safety. Heartbeat Technology enables you to optimize proof testing of your SIS, maintaining state-of-the-art plant safety without compromising availability – all with minimal effort. Integrated in a wide range of our instruments, this technology delivers concise, standardized diagnostic notifications and monitoring data that allow you to service and maintain your systems precisely when its needed.

Key facts

31

countries with trained safety ambassadors ready to discuss your safety concerns

Key facts

100+

SIL-certified devices to provide the best solution for your application

Key facts

10

million devices installed in safety-related applications over the past 65 years

How we can help

Endress+Hauser offers intelligent Heartbeat Technology to ensure optimal SIS proof testing, as well as rigorous SIS proof testing services, enabling sustained plant safety with minimal process interruption for the chemical industry:

- Permanent process and device diagnostics with a diagnostic coverage of up to 98%

- Standardized diagnostic messages with precise instructions

- Verification without process interruption via the push of a button

- Automatically generated and unambiguous verification protocols

- Safety Integrity Level (SIL) verification through a wizard-assisted proof test procedure that unveils dangerous undetected failures