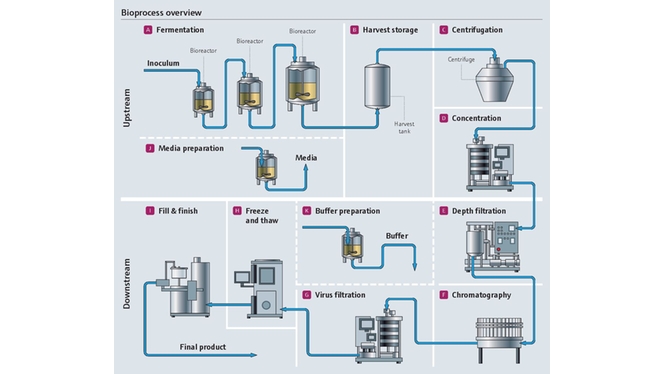

The life sciences industry continuously faces new challenges. Broad sections of the population need to be supplied with affordable drugs. While high research costs demand high productivity and reliability, pharmaceutical companies must provide consistently high drug quality at lower cost. Maintaining profitability, global manufacturing and cost awareness are important. Innovative solutions for the pharma industry are more and more requested in this context. We have some ideas for you.

Key facts

8%

productivity growth

due to less plant downtime thanks to integrated calibration concepts

Learn how to control costs in pharma manufacturing

Implement innovative temperature measurement

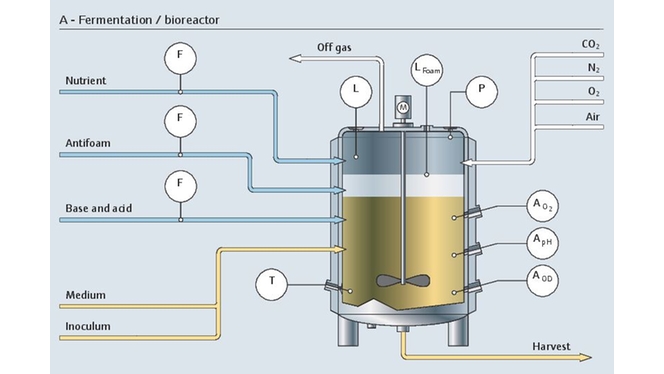

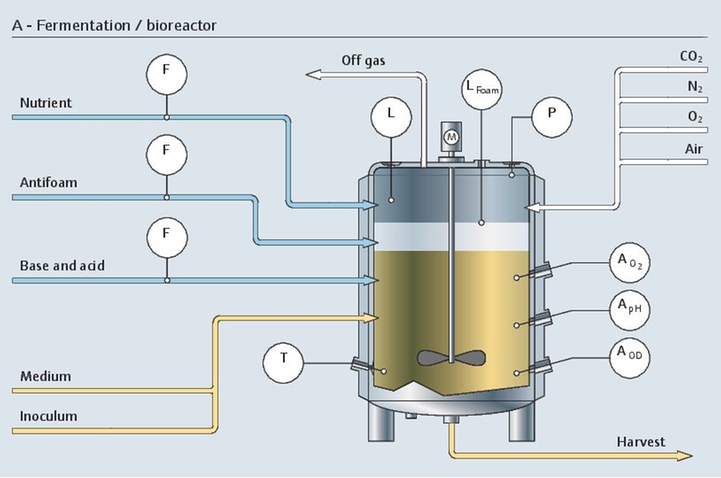

For pharmaceutical companies temperature is one of the main critical measurement points in a bioprocess with strong impact on both, cell kinetics and solubility of dissolved gases. Temperature influences reaction kinetics, cell growth, cell viability and product formation. Therefore narrow-band temperature control and frequent calibration are necessary to meet process requirements and accuracy, which can be costly.

Our expertise in the field

To ensure optimum output and quality, temperature devices should be calibrated regularly. In critical applications a six-month-interval is common. Using innovative measurement technology can reduce calibration effort and costs significantly. Which is why we developed the world's first self-calibration temperature sensor TrustSens TM371. This innovative device offers you fully automated, traceable, inline self-calibration that will help you eliminate nonconformities or undetected failures.

Standardize your installed assets

Uniform operation and quick replacement of devices: this might sound easy, but it is not. Gaining and maintaining full transparency of the many assets installed over time in your pharmaceutical company is a constant challenge that significantly increases maintenance efforts. Analyzing your installed assets for manufacturing is the first step to optimized maintenance efficiency and plant availability.

Our expertise in the field

Analyzing your installed assets for manufacturing is the first step to optimized maintenance and plant availability. During this process our experts can identify obsolete or outdated instruments which can then be easily replaced. Not only will your spar parts logistics drastically improve by standardizing your assets, you will also be able to improve and streamline your training efforts in a standardized environment.

Verify instrument functionality

Maintenance and calibration are often considered a time-consuming and cost-intensive nuisance. However, both maintenance and calibration are key when it comes to safeguarding process reliability and product quality in the manufacturing of pharmaceuticals.

Our expertise in the field

Instruments equipped with Heartbeat Technology significantly extend test cycles and supply standardized diagnostic notifications for cost-effective maintenance. The technology offers simple and easy monitoring of the measurement points during daily operation. Errors are recognized in an early stage and is production increased. Instrument verification validates that all critical components are working properly within the defined specification.

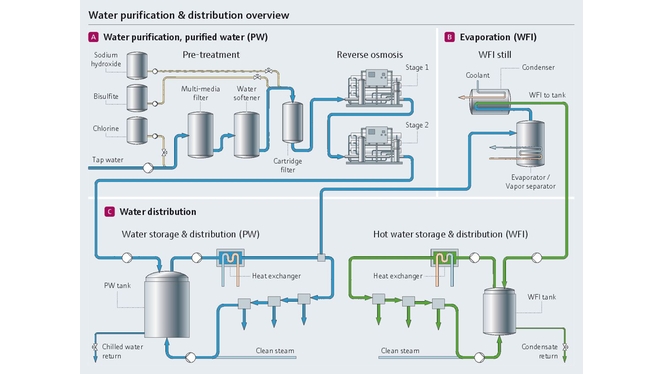

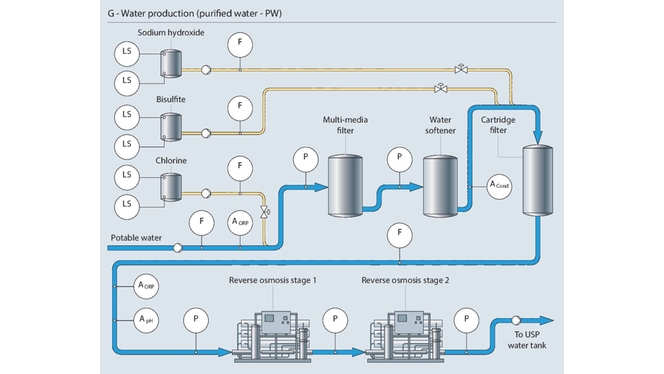

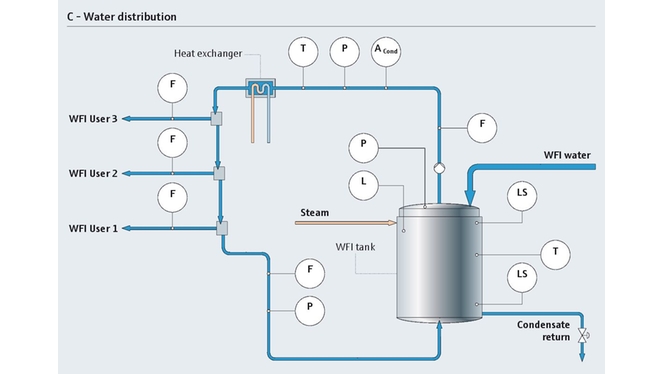

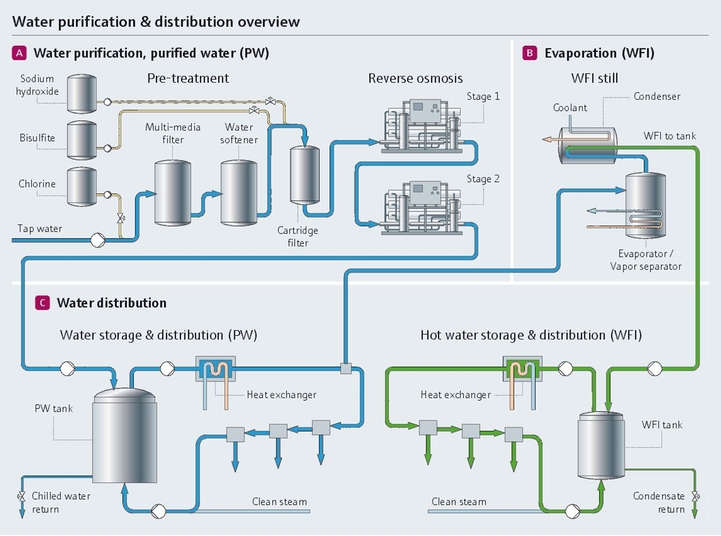

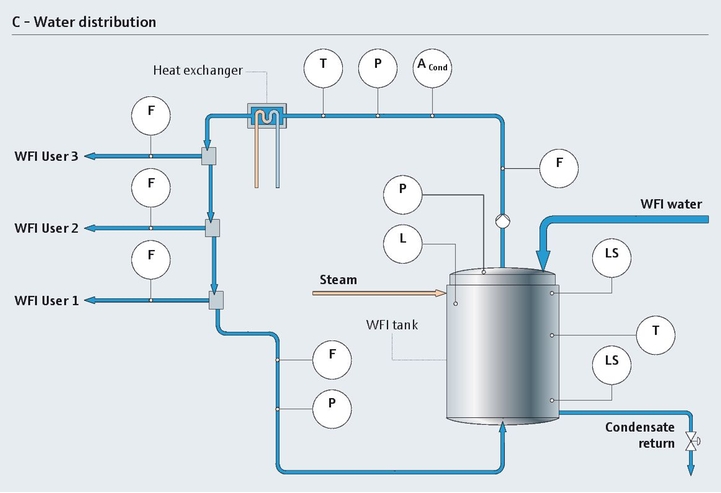

Optimize your water production and distribution

In order to prevent bioburden, water must be continuously in motion at a flow speed above 2 m/sec. Reliable flow measurement is thus fundamentally important and critical measurement points must be calibrated regularly. When it comes to purified water (PW) and water for injection (WFI) conductivity is the main quality parameter. The limits defined in the pharmacopeias must always be met.

Our expertise in the field

With Heartbeat Technology our instruments provide reliable self-monitoring and help optimize your calibration procedures, especially in continuous processes. This directly results in higher plant availability and manufacturing. In PW and WFI non temperature compensated conductivity measurement in the low range is a basic requirement. The system calibration in the distribution loop is an efficient way to assure regulatory compliance. To optimize your water production we offer:

- Highly accurate flow measurement

- Reliable conductivity monitoring

- Easy and fast calibration

- Self-diagnostic and effortless verification

Benefits

Master the future challenges together with our specialists and benefit from their many years of experience in the life sciences industry. They provide a thousand ideas on how to reduce costs in pharma manufacturing, help support you to reach your goals and achieve operational excellence.

Key facts

10%

cost reduction thanks to preventive maintenance concepts

Key facts

60%

less SOPs for calibration

Key facts

94%

total test coverage with Heartbeat Technology

How we can help

Our pharmaceutical industry experts have many ideas on how to reduce costs in manufacturing while improving operational excellence. Using our innovative measurement technology and maintenance concepts can reduce your calibration effort and costs significantly. To control your costs, you should consider to:

- optimize calibration or install self-calibrating temperature measurement devices

- standardize your installed assets, optimize your stock and increase the availability of spare parts

- integrate and evaluate diagnostic data and verify instrument functionality

- optimize your water production and distribution loop